- Stock: In Stock

- Brand: Other

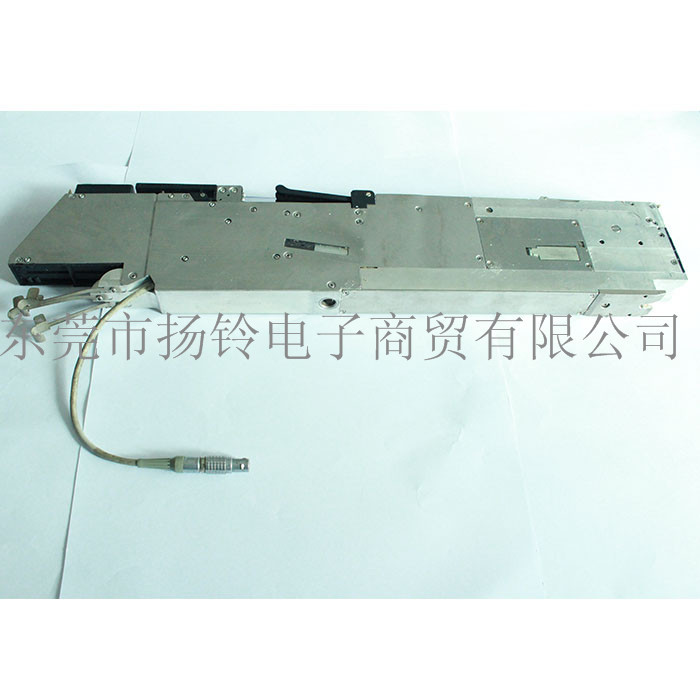

- Model: EF241111BS2801

- Weight: 999.99kg

Available Options

GKG Gse automatic solder paste printing machine is a high-precision and high-stability automatic visual printing machine, GKG company followed the development trend of the SMT industry to produce a new generation of automatic visual printing machine and technology synchronization, high-resolution visual processing, high-precision drive system, suspended adaptive squeegee, the board positioning processing and dexterous mesh frame clamping structure, compact structure, both accuracy and high degree of flexibility, GKG Gse automatic solder paste printing machine provides customers, printing the required functions, more customers to provide outstanding cost-effective. With its compact structure, accuracy and high flexibility, the GKG Gse Automatic Solder Paste Printer provides customers with the functionality they need for printing, and even more so with an outstanding price/performance ratio.

GKG Gse automatic solder paste printing machine main technical parameters:

(1) Printing accuracy: ± 0.025mm

(2) Repeatability: ±0.01mm

(3) Printing cycle time: <7.5s

(4) Screen frame size from 420×520mm-737×737mm

(5) Printing PCB size from 50×50mm-400×310mm.

GKG Gse Automatic Solder Paste Printing Machine Product Features:

1. GKG Gse Automatic Solder Paste Printing Machine manually adjustable jacking platform structure is simple and reliable, low cost, easy to adjust manually, which can quickly realize the adjustment of PIN pin jacking height of PCB boards with different thicknesses.

2. image and light system new light system - uniform ring light and high brightness coaxial light, with infinitely adjustable brightness function, so that all types of Mark points can be well identified (including uneven Mark points), to adapt to tin plating, copper plating, gold plating, spraying tin, FPC, and other types of different colors of the PCB.

3. Squeegee system: Slide-type squeegee system to improve operational stability and prolong service life.

4. Cleaning system new wipe rubber strip to ensure that the full contact with the stencil, plus large vacuum suction to ensure that vigorously eliminate the residual solder paste in the mesh, to achieve effective automatic cleaning function: dry and wet vacuum three cleaning modes, the software can be set at random to clean the cleaning mode and length of the cleaning paper

5. Stable stencil fixing structure

6. Perfect 2D inspection system

| After-sales Service | One-year after-sales service |

| Applicable Object | Electronic |

| Material Compatibility | Cardboard |

| Maximum Frame Size | 0 |

| Maximum Printing Area (Length × Width) | 0 |

| Operation Method | Fully Automatic |

| Outer Dimensions | 1362*1463 |

| Power Supply | 220V |

| Printed Surface | Plane |

| Printing Color | Bicolor |

| Printing Material Thickness Range | 0 |

| Printing Speed | 0 |

| Processing Customization | No |

| Product Type | New |

| Weight | 1000 |

| Workbench Size | 0 |

| Workbench X-Y Adjustment Range | 0 |