- Stock: In Stock

- Brand: Fuji

- Model: EF241101CS1004

- Weight: 0.50kg

Available Options

Product Details

Product Name:Mounter Nozzle

Model:0.4 0.7 1.0 1.3 1.8 2.5 3.7 5.0

Applicable models:XP141 142 143 XPF

Technical Parameters

Technical Parameters  Characteristics

Characteristics  Instructions for use

Instructions for use 1. The air pressure at the mouth of the suction nozzle is controlled at a relatively low level, which

The SMD components inside the suction nozzle are adsorbed to the mouth under the action of air pressure.

2、When the mounter detects the position of components to be mounted, it will start the vacuum

Suction nozzle, the use of vacuum pump generated by the negative pressure of the SMD components from the solder paste sucked up.

3、SMD components inside the nozzle are moved to the desired position under the joint action of air pressure and vacuum suction.

moved to the desired position.

4、When the SMD component reaches the desired position, the air pressure is released to keep the SMD component in position.

When the SMD component reaches the desired position, the air pressure is released to keep the SMD component in position.

5. The mounter will use a robotic arm or electrode to place the SMD component on the PCB board to complete the placement process.

The whole process relies on the control system of the mounter. The entire process is controlled by the mounter control system to

to ensure the accuracy and precision of the placement.

Packing List

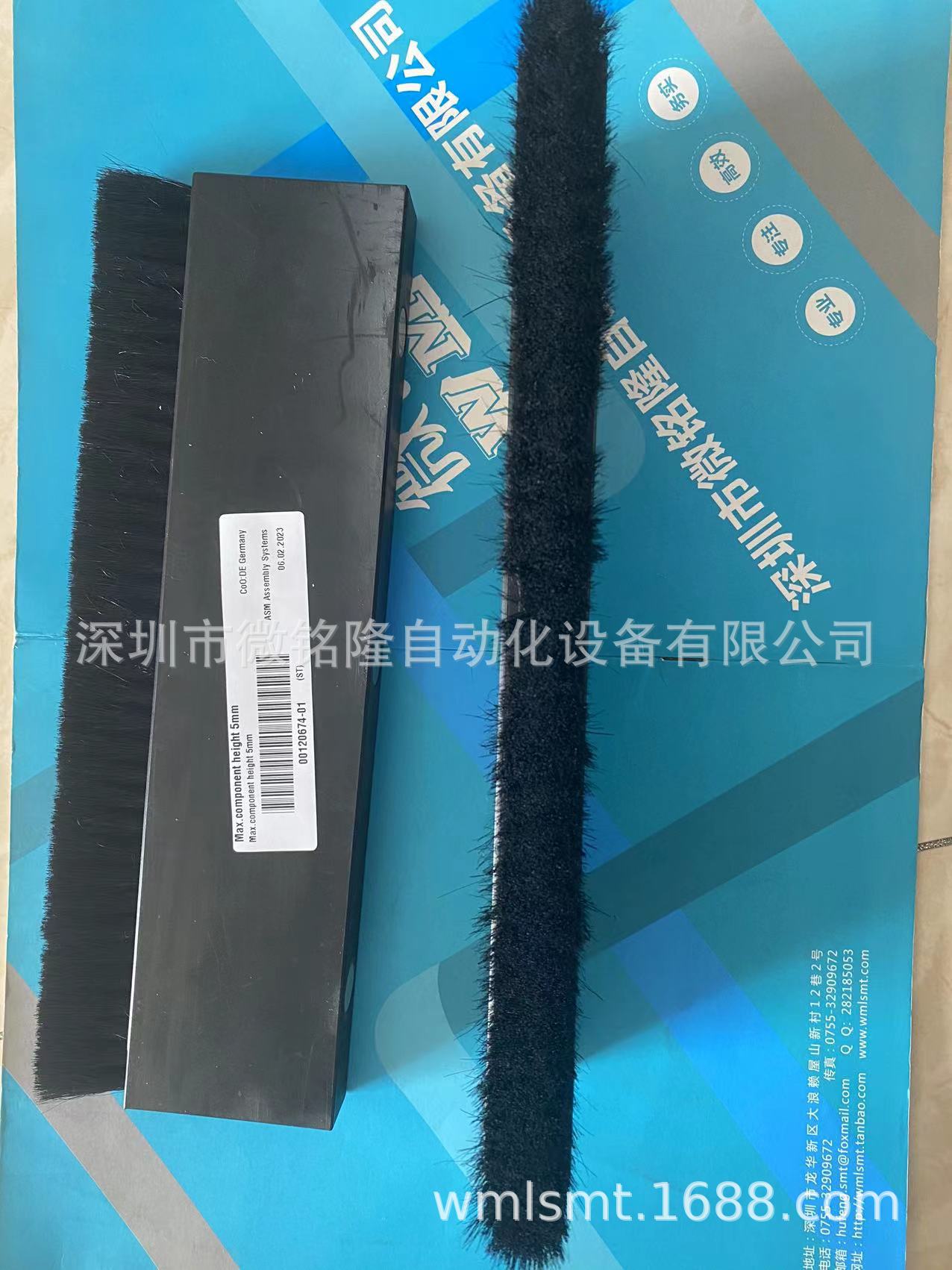

Packing List 1.Transparent box

2.Nozzle black

Uses/Applications

Uses/Applications The role of the bonder nozzle:

With the development of integrated circuits, the market chip volume miniaturization, high precision and

High technical requirements and high demand. People have been unable to meet the market requirements for mounting, automated mounter equipment began to replace manual labor.

Automated mounter equipment began to replace manual labor. The suction nozzle is a component on the mounter.

Components are the use of this suction nozzle, adsorption after moving to the designated location, the

When the mounter's suction nozzle sucks up the components, to achieve the ideal situation, it is necessary to ensure that the center of the components, the suction nozzle

The center of the component, the center of the suction nozzle and the center of the acquired image space should be coincident.

The center of the component, the center of the nozzle and the spatial center of the acquired image should be coincident.More effectively improve production efficiency, to meet market demand.

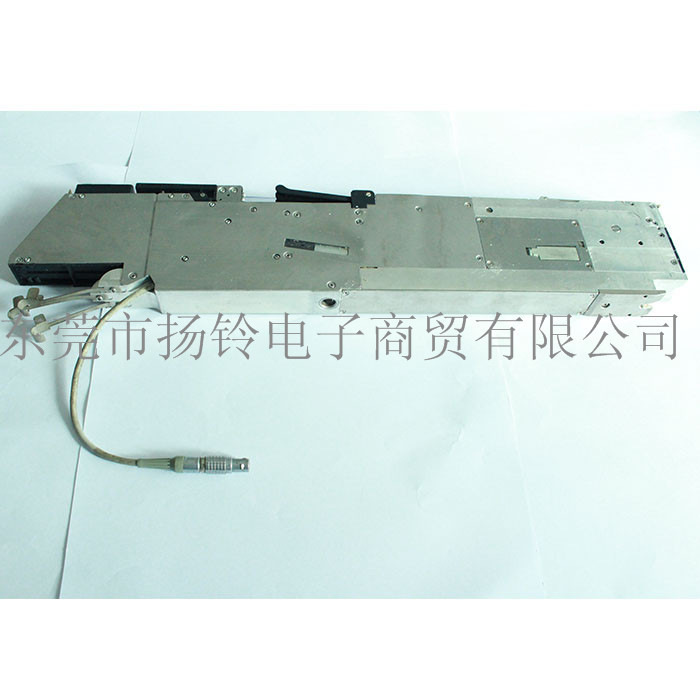

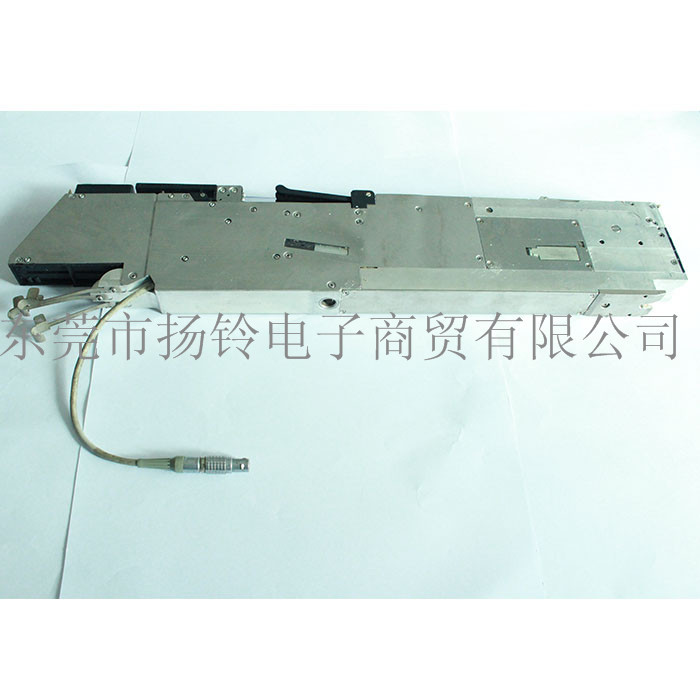

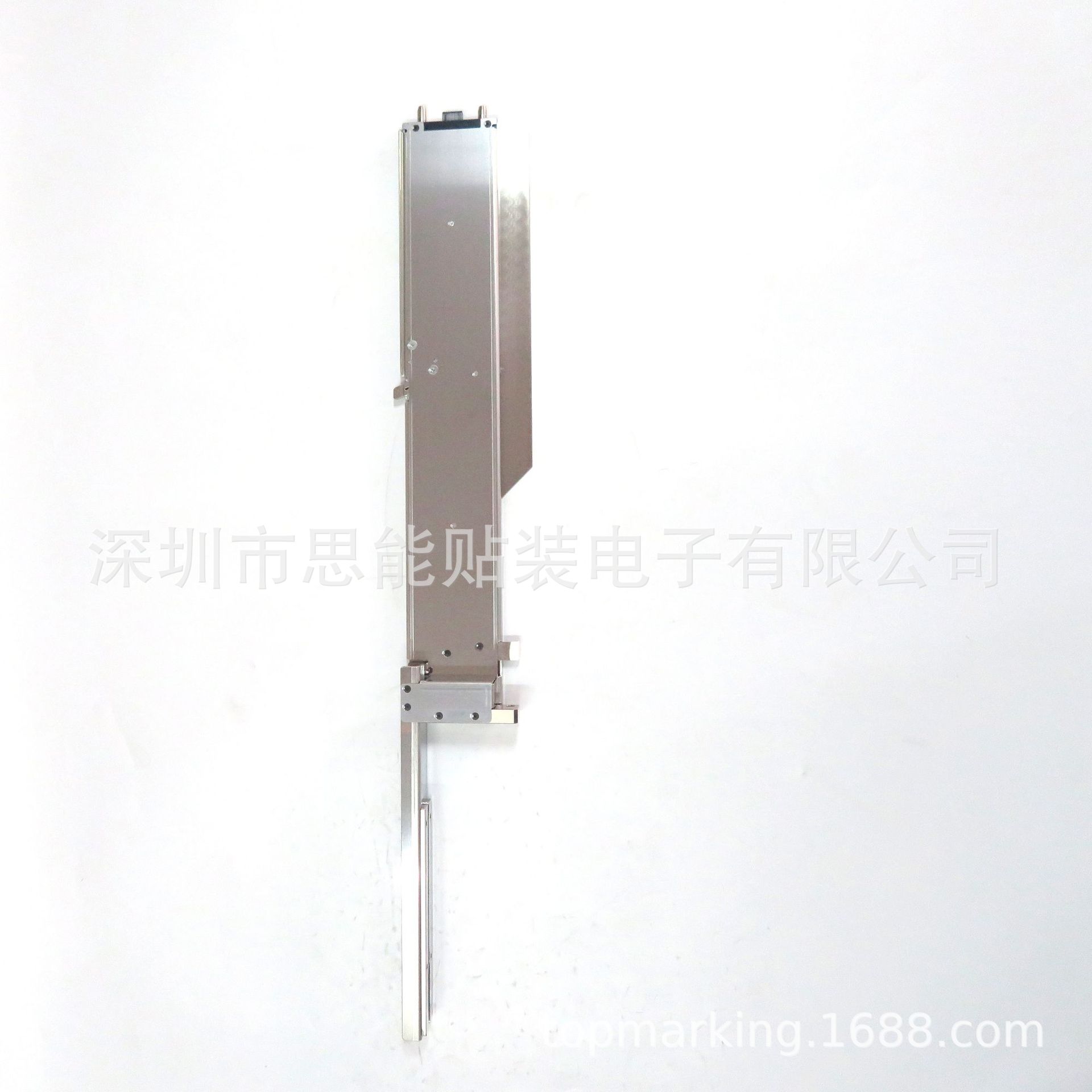

Product Picture

Product Picture XP141 142 143 XPF Mounter Nozzle

0.4 0.7 1.0 1.3 1.8 2.5 3.7 5.0

| Country of Origin | Japan |

| Place of Origin | Shenzhen |

| Usage | Placement Machine |