- Stock: In Stock

- Brand: Fuji

- Model: EF241028QG1240

- Weight: 10.00kg

Available Options

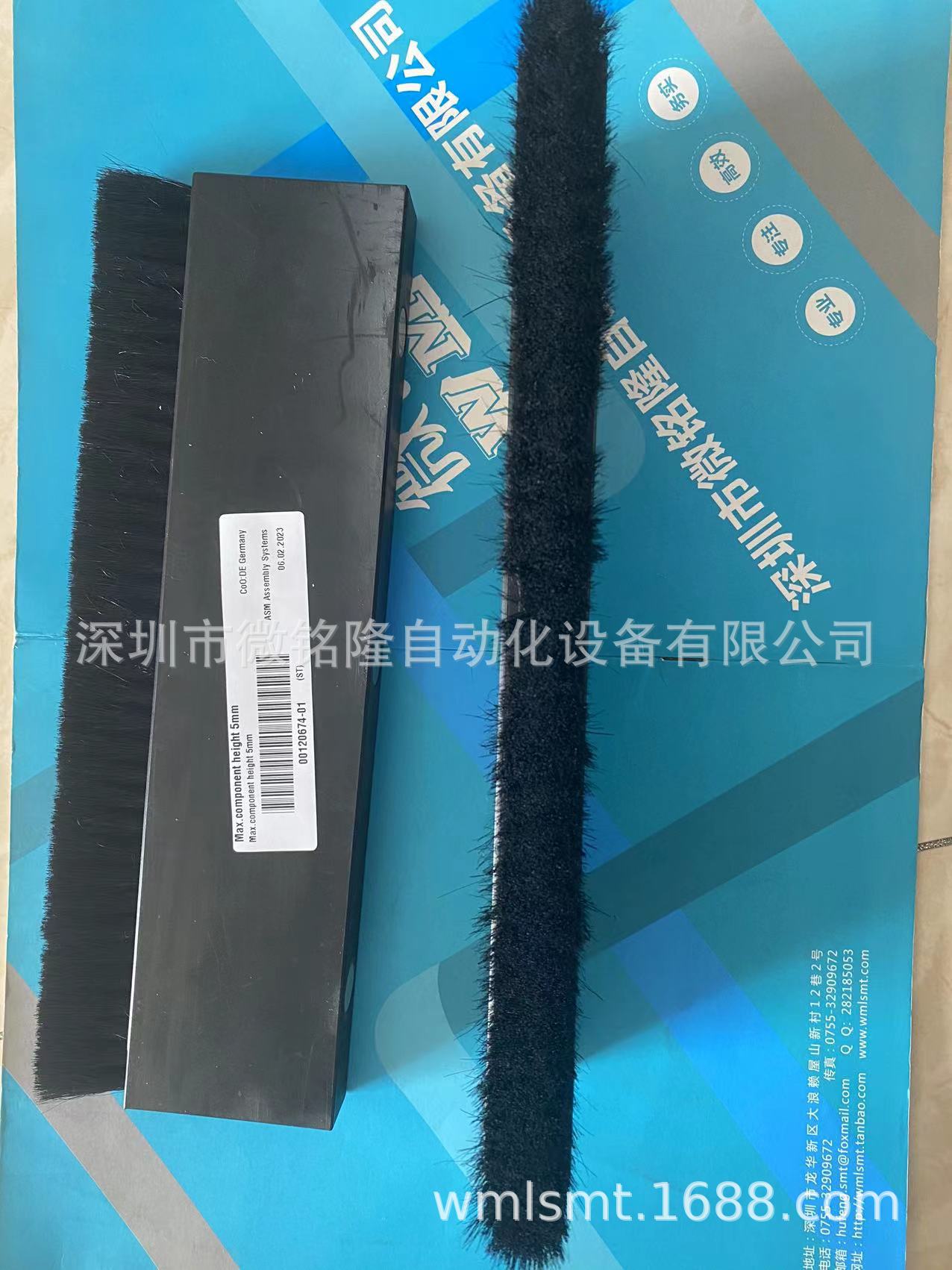

SMT Mounter Accessories Consumables For Fuji FUJI NXT LB FUJI Label FEEDER Rack Feeding

Mounter Intelligent Label Feeder (AREED LABEL FEEDER FOR NXT)

Functional Features

1.Universal for FUJI NXT mounter, no need to buy a separate labeling machine, greatly saving plant space and equipment costs.

2.Applicable to a variety of size labels, paper, plastic and foam labels, can complete the labeling task.

3.Independent independent development software, touch screen control interface, simple, practical and humanized.

4.System software based on Arm customization, with 3.2-inch touch screen, simple and effective operation. Fidelity and tray two working modes, corresponding to the different working modes of single column and multi-column labels.

5.Highly sensitive fiber optic sensors locate the position of the labels to ensure that each feeding is accurate; Feeding fault braking system to prevent label waste caused by abnormal work.

6.Peeling gap can be self-adjusted to meet the different requirements of a variety of thickness and height of the label; label width is adjusted according to the need to achieve multi-column label feeding at the same time.

7.42-type stepping motor with 5.18:1 reducer, power and high torque output; self-developed drive circuit ensures smooth and low noise operation of the motor.

Main Specifications and Technical Parameters

Item | Model | NXT-LB |

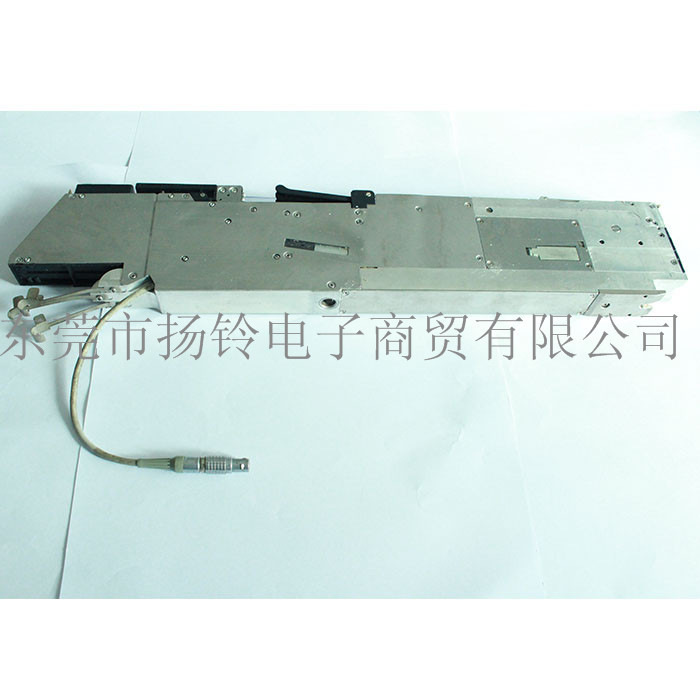

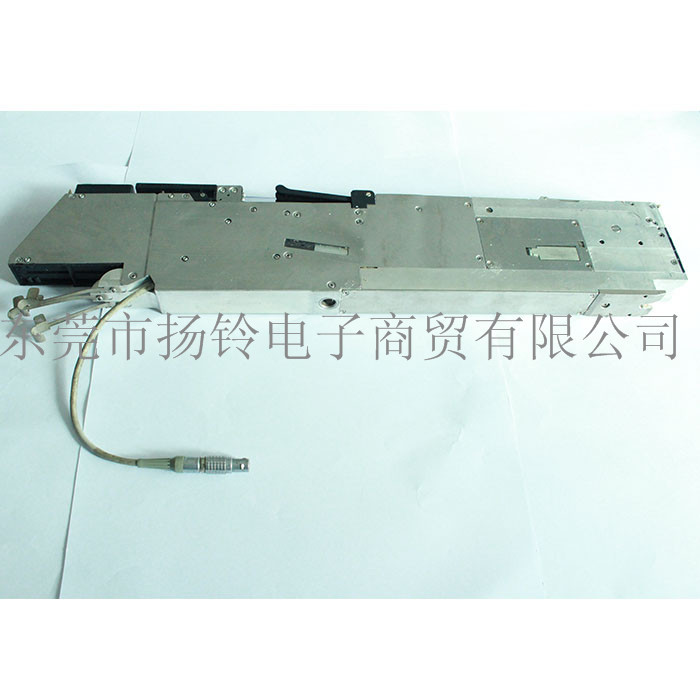

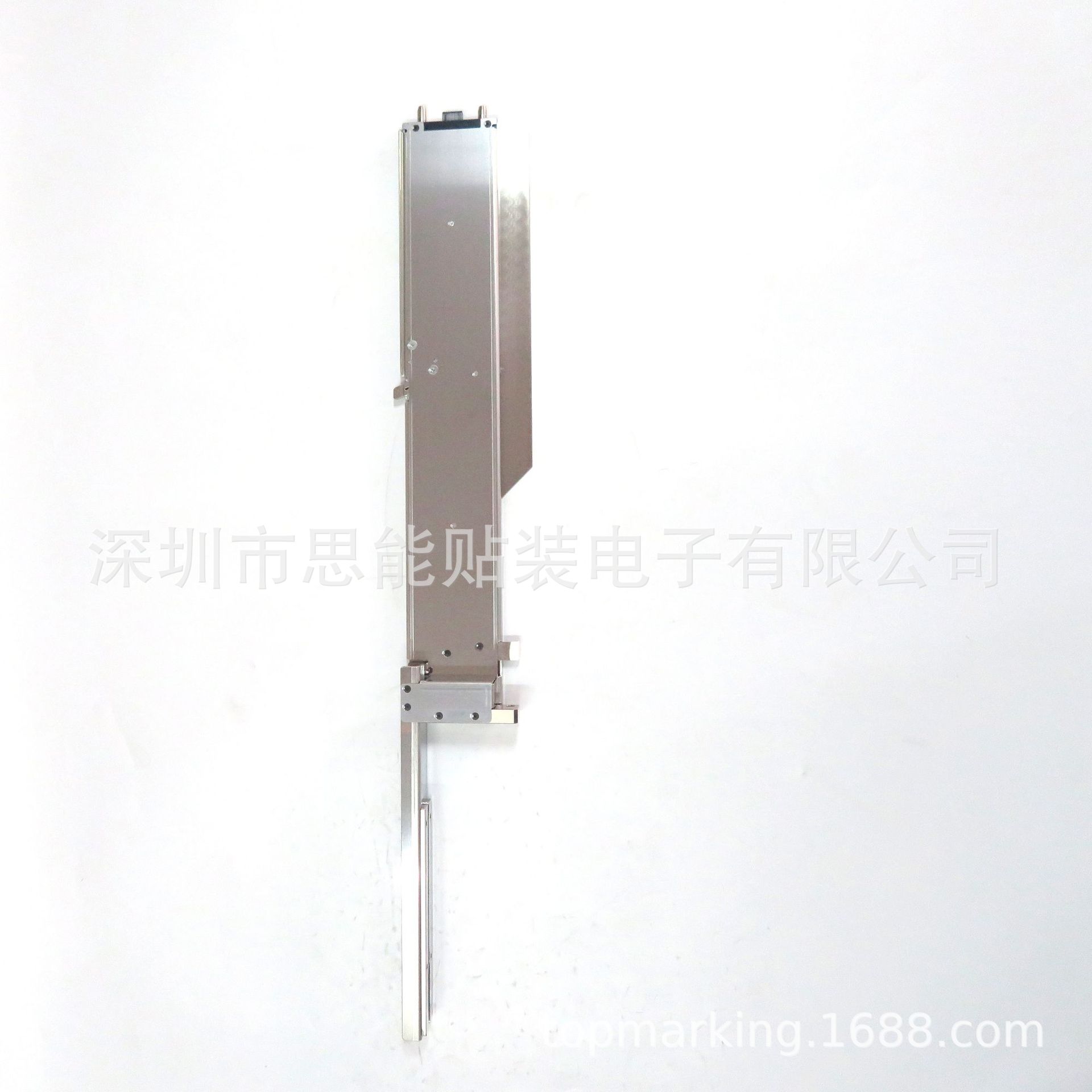

Appearance size | Length | 670.5mm |

Width (mm) | 124mm | |

Height (mm) | 289mm | |

Weight | 6kg±50g | |

Main Material | Aluminum alloy | |

Positioning method | "Work" type guide rail | |

Human-machine interface | 3.2 inch touch screen | |

Voltage | 24V | |

Average current | 0.8A | |

Peak Current | 2A | |

Communication Mode | RS232 | |

Simplified Mode | Pulse | |

Software control | Customized based on Arm | |

Driving method | Stepper motor 42 type piggyback | |

Motor speed | 5.18:1 gearbox | |

Stepping angle | 1.8°±5 | |

Feeding speed | 5 speeds | |

Feeding precision | X-axis direction ±0.1mm, Y-axis direction ±0.1mm | |

Patch precision | 2mm-60mm | |

Trial package | Tape point width <60mm | |

Stripping method | Peeling knife | |

Changing method | Stop the machine and change the material manually | |

Waste material recycling | Tape and Reel Recycling | |

Anti-mistake material | Intelligent braking system | |

Aging test | 72 hours of continuous operation without any abnormality | |

Operation record | Complete and consistent | |

Service life | 3~5 years | |

Hanging mode | Rear mounted hangers | |

Component Positioning Mode | Fiber optic sensor positioning | |

Working Mode | Autonomous feeding/10 trigger | |

| Alias | Labeling Feeder |

| Applicable Machinery | Placement Machine |

| Model | LB Labeling Feeder |