- Stock: In Stock

- Brand: Fuji

- Model: EF241120UT1105

Available Options

For the SMT industry, Fuji mounter FUJI is a relatively cost-effective machine, NXT belongs to the FUJI FUJI is the masterpiece of the mounter, from 2004 to now in 2014, NXT has been very mature. In NXT's working head, there is an accessory, belongs to the wearing parts, A5053C, also known as A5054X, is an O-ring, also known as sealing ring, used in NXT's H12S working head, also used in the H12 working head, H12HS working head, V12 working head, the working head, also known as the mounting head. So many working head need to use A5053C, A5054X, the most vulnerable to wear is also this NXT accessories, but in FUJI accessories is very small, the unit price is relatively cheap, a NXT mounting head H12S only with 72 A5053C, or A5054X. a mechanical valve SPOOL inside, there are 6 such seals A5053C, A5054X, if H04HHS, H12HS, V12 working head, working head is also known as the mounting head. A5054X, if H04S there are 24. If H08 head, there are 48 of them.

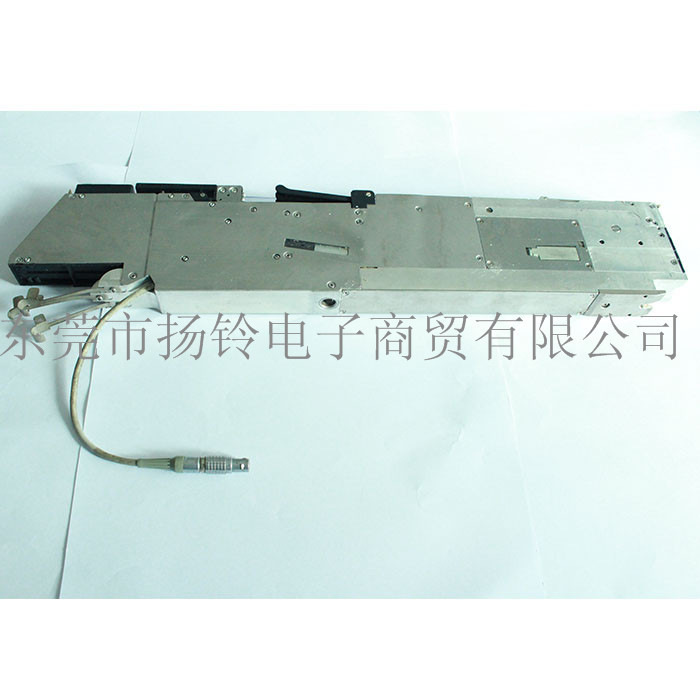

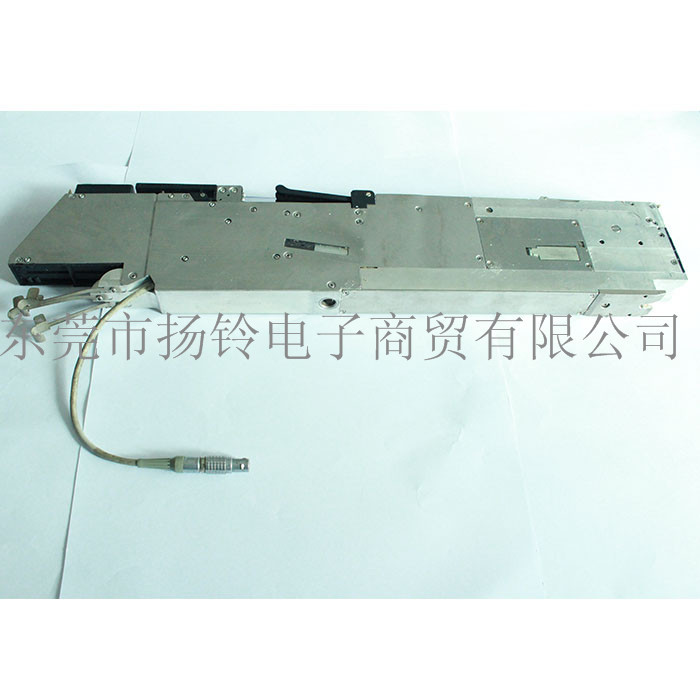

Z-axis screws

Product name: Z-axis screw

English name: BALL SCREW

Material No.: GFPH254

Use:XP143E

How to distinguish between SMT FUJI Fuji original parts and imitation parts:

Original:

Better material, wear-resistant, longer service life;

High precision, good mounting effect;

Smooth nozzle hole, not easy to block the hole;

Reflective effect is good, recognize the nozzle is more accurate.

Imitation:

Poor material, not wear-resistant, shorter service life;

Poor precision, which has an impact on the quality of the mounting;

Smaller suction nozzle holes, easy to plug the holes, resulting in insufficient vacuum, poor pick-up, throwing material serious;

Reflective effect is poor, recognize the suction nozzle is easier to cause recognition error.

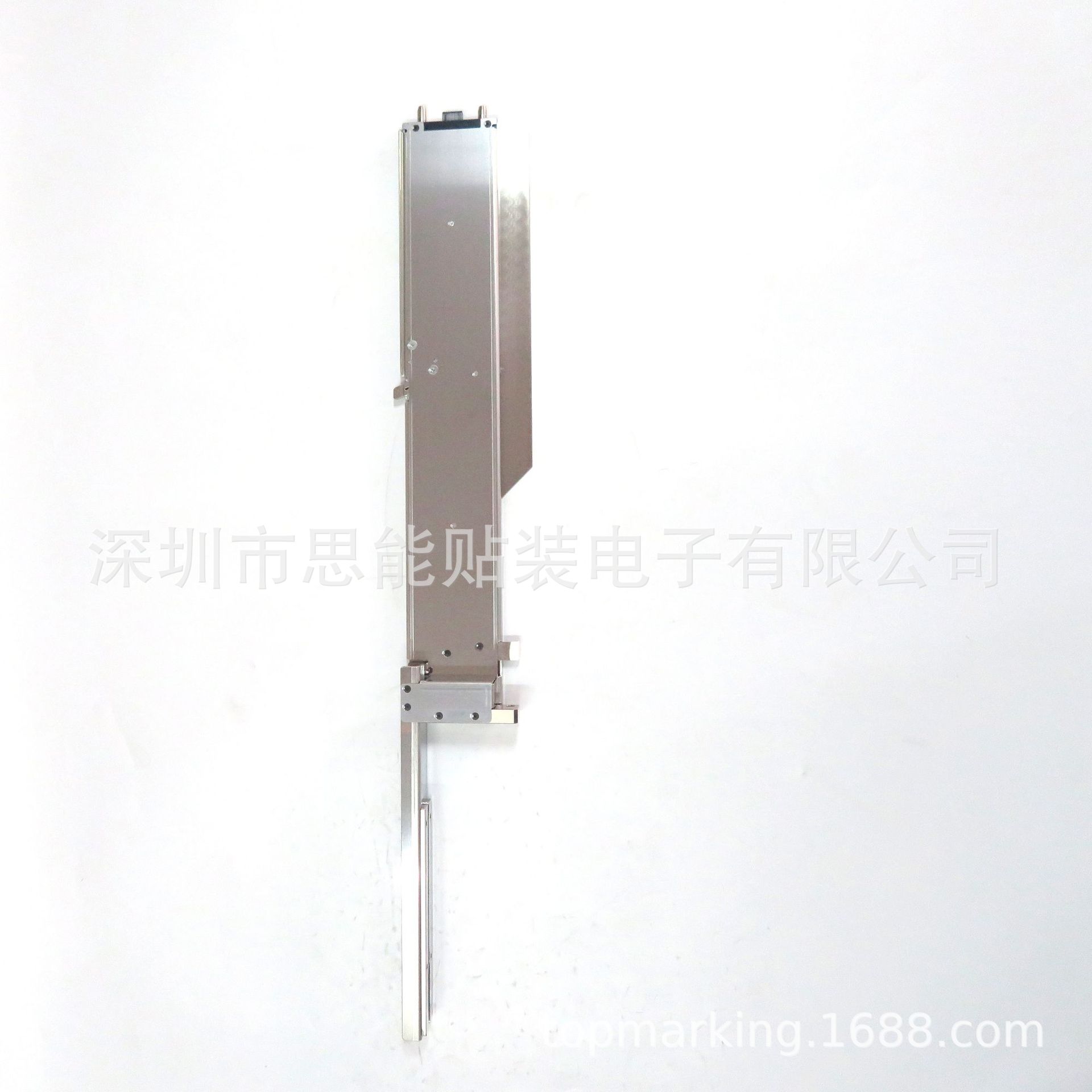

XP143E machine, belonging to FUJI Fuji in 2005 launched the market compact high-speed mounter, it has a small size, speed, applicability, cost-effective advantages.

The XP143E is a full-image mounter that realizes high-speed placement and compact machine space, and can be used for high-speed placement of small chip components to medium-sized components (25 x 20mm) and further to BGA and CSP (20 x 20mm).

The main parameters are as follows.

Mounter speed: 25000 cph (12 nozzle) ; 9000 cph (1 nozzle)

Mounter accuracy: +/- 0.050mm @3 sigma (chip); +/- 0.040mm @3 sigma (QFP).

Board size: 50 X 50mm -- 457 X 356 mm

Component size: 01005 X 20 mm (12 nozzle) ; 0402 X 150 mm (1 nozzle)

Standard description:

Electronic board size: Maximum: 457 X 356 mm; Minimum: 50 X 50 mm

Electronic board thickness: 3--4.0mm

Component type: Maximum 100 types (front side, rear side each 50 types)

Circuit board loading time: 4.2 seconds

Mounting Accuracy:±0.050mm cpk≧1.00 : Rectangular components, etc.; ±0.040mm cpk≧1.00 : QFP, etc.

Mounting Speed:0.165/second/piece,21,800pcs/hour:Rectangle Component;0.180/second/piece,20,000pcs/hour:0402

Object component: 0402-25mm*20mm Maximum height: 6mm

Machine dimensions: L: 1,500mm/W: 1,300mm/H: 1,408.5mm (excluding signal towers)

Machine weight: Approx. 1,800KG (main body)

| Model | XP143E |

| Power Supply | 1 |

| Processing Customization | Yes |

| Weight | 1 |